© 2023, Meta Systems LLC

RevPi Core

Powered by the Raspberry Pi Compute Module, the base modules are the core of every Revolution Pi modular system.

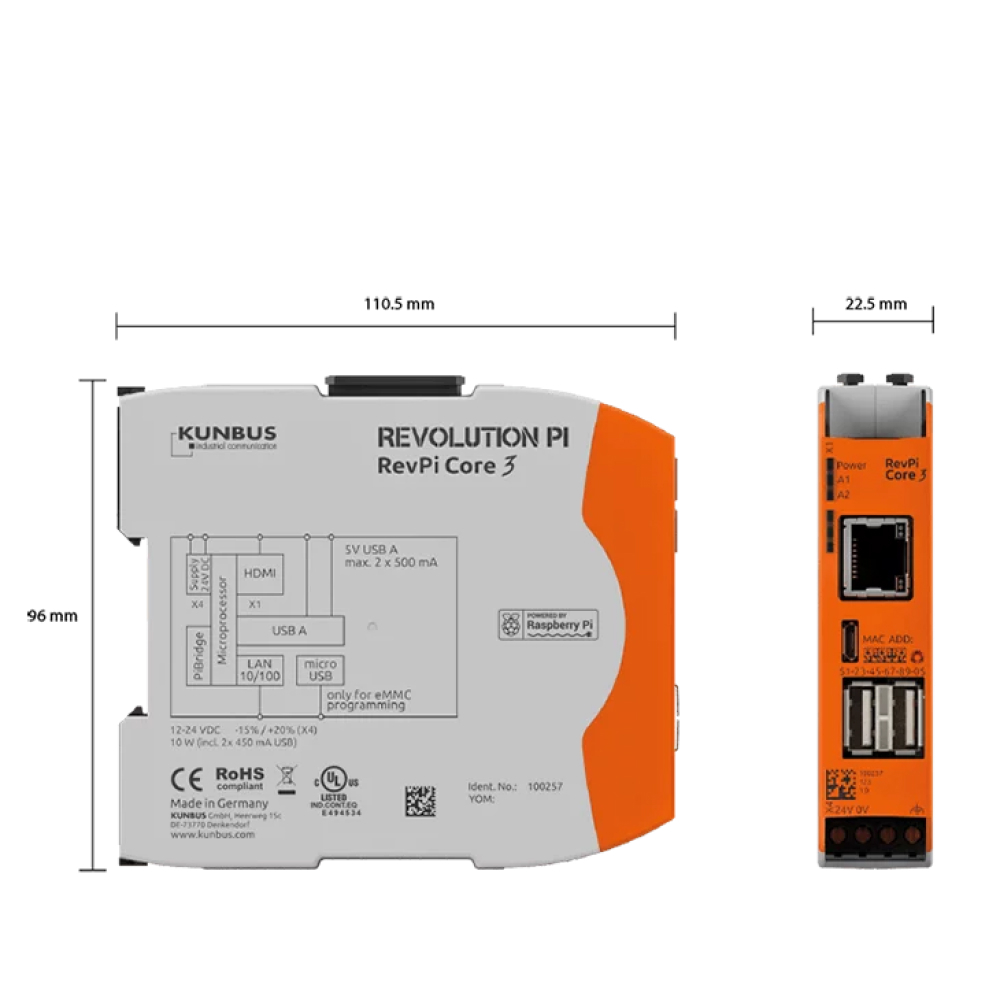

The RevPi Core is with 22.5mm only half as wide as the RevPi Connect, but has twice as many PiBridge connectors, namely two. This means that the RevPi Core can be upgraded with up to 10 expansion modules. Like the RevPi Connect series, the RevPi Core series is also equipped with the Raspberry Pi Compute Module 3, Compute Module 3+ or Compute Module 4S, depending on the variant. A Real Time Clock (RTC) with 24 h buffering ensures that the device always knows what time it is, even in the event of a power failure. As with all Revolution Pi base modules, a specially adapted version of Raspbian with real-time function is used as the operating system.

The RevPi Core is with 22.5mm only half as wide as the RevPi Connect, but has twice as many PiBridge connectors, namely two. This means that the RevPi Core can be upgraded with up to 10 expansion modules. Like the RevPi Connect series, the RevPi Core series is also equipped with the Raspberry Pi Compute Module 3, Compute Module 3+ or Compute Module 4S, depending on the variant. A Real Time Clock (RTC) with 24 h buffering ensures that the device always knows what time it is, even in the event of a power failure. As with all Revolution Pi base modules, a specially adapted version of Raspbian with real-time function is used as the operating system.

Following RevPi Core versions are available

Generally, the only difference between the RevPi Core variants mentioned above are the built-in Raspberry Pi compute modules. The exception here is the RevPi Core SE variant, which does not support the gateway expansion modules.

- RevPi Core S — powered by Compute Module 4S

- RevPi Core SE — powered by Compute Module 4S

- RevPi Core 3+ — powered by Compute Module 3+

- RevPi Core 3 — powered by Compute Module 3

Full power

The power supply circuit is one of the most important parts of the

RevPi Core. In order to get as small heat from power dissipation as possible we are using state-of- the-art high-efficiency DC-DC-converter (efficiency over all is greater than 80 %). These converters use 24 VDC input (which is the usual case in industrial applications) to produce all supply voltages needed for the Core.

But our Core module does not only run on the standardized supply range of 20.4 V to 28.8 V but also runs on as little as 10.2 V input voltage*. That means you can even use car batteries or solar panels as power supply. At 24 V input any power loss of up to 10 ms will not influence operation of RevPi Core (drawing full current from both USB ports) and even up to 25 ms without

USB load. Input voltage and functional earth is connected to RevPi Core using heavy duty connectors at the bottom side.

RevPi Core. In order to get as small heat from power dissipation as possible we are using state-of- the-art high-efficiency DC-DC-converter (efficiency over all is greater than 80 %). These converters use 24 VDC input (which is the usual case in industrial applications) to produce all supply voltages needed for the Core.

But our Core module does not only run on the standardized supply range of 20.4 V to 28.8 V but also runs on as little as 10.2 V input voltage*. That means you can even use car batteries or solar panels as power supply. At 24 V input any power loss of up to 10 ms will not influence operation of RevPi Core (drawing full current from both USB ports) and even up to 25 ms without

USB load. Input voltage and functional earth is connected to RevPi Core using heavy duty connectors at the bottom side.

A sophisticated protection circuit guarantees continuous operation even under massive electrical or electro-magnetic interference on the input power lines (provided that functional earth is connected properly). Lightning strikes and nearby welding machines have been simulated in our test laboratories but could not impress our RevPi Core modules.

In addition, the Revolution Pi has a Real Time Clock with 24 h buffering, which ensures that the device always knows what time it is, even in the event of a power failure.

In addition, the Revolution Pi has a Real Time Clock with 24 h buffering, which ensures that the device always knows what time it is, even in the event of a power failure.

For whom?

Industrial Automation Specialists — Automation specialists need the RevPi Core because it offers a powerful and reliable platform for control applications, with features such as real-time operation, modular I/O system and communication with industrial protocols such as Modbus and CANopen.

Control Engineers — RevPi Core provides control engineers with a compact, powerful and flexible platform for building control systems. It supports real-time operation and features multiple interfaces for communication with sensors, actuators and other components.

Industrial IoT Specialists — With support for Ethernet and wireless communication protocols, it can be used to collect and transmit data from sensors, machines and other devices. The ability to integrate with cloud-based systems, provides industrial IoT specialists with the ability to remotely monitor and control their production processes.

Robotics Specialists — RevPi Core is a compact and powerful platform for building robotic systems. With support for real-time operation and a variety of interfaces for communication with sensors and actuators, it provides robotics specialists with a flexible solution for controlling and monitoring their robotic systems.

Technical information RevPi Core

Interfaces

- Like Raspberry Pi, RevPi Core is equipped with common interfaces.

- Ethernet plug

- USB plug

- Micro USB plug

- Micro HDMI plug

- 1 x RJ45 Ethernet sockets

- 2 x USB 2.0 sockets

- 1 x Micro HDMI socket

- 1 x Micro USB 2.0 socket

- 2 x PiBridge (for RevPi Con expansion modules)

Highly modular

One of our major goals was to make Raspberry Pi ready for tough industrial environment, so it could become a real IPC which meets the EN 61131-2 standard.

- The data highway connecting all RevPi modules is called PiBridge. The modules are physically connected to each other, using a system connector on the top side. Three signal types are exchanged via this connector:

- 4 pins of the PiBridge are used for automatic module detection during start up phase. After this phase RevPi Core exactly knows which modules are connected and in which physical position they are.

- 4 pins of the PiBridge are used for rapid data exchange of small data packages using RS485 signals. This channel is also used for module configuration during start up phase. After configuration this channel is used for cyclically exchanging data between RevPi Core and all IO modules connected.

- 8 pins of the PiBridge are used for rapid data exchange of large amount of data using Ethernet signals. Up to now this channel is only used by our modular gateway modules which may collect up to 512 Byte data cyclically from nearly all relevant fieldbusses. emote maintenance

One of our major goals was to make Raspberry Pi ready for tough industrial environment, so it could become a real IPC which meets the EN 61131-2 standard.

- Power supply: 12-24 VDC -15 % / +20 %, max. 10 W

- Operating temperature: -25 °C to 55 °C

- ESD protection: 4 kV/8 kV according to EN 61131-2 and IEC 61000-6-2

- Surge / Burst tests: applied according to EN 61131-2 and IEC 61000-6-2

- EMI tests: according to EN 61131-2 and IEC 61000-6-2

- UL certified (UL-File-No. E494534)