© 2023, Meta Systems LLC

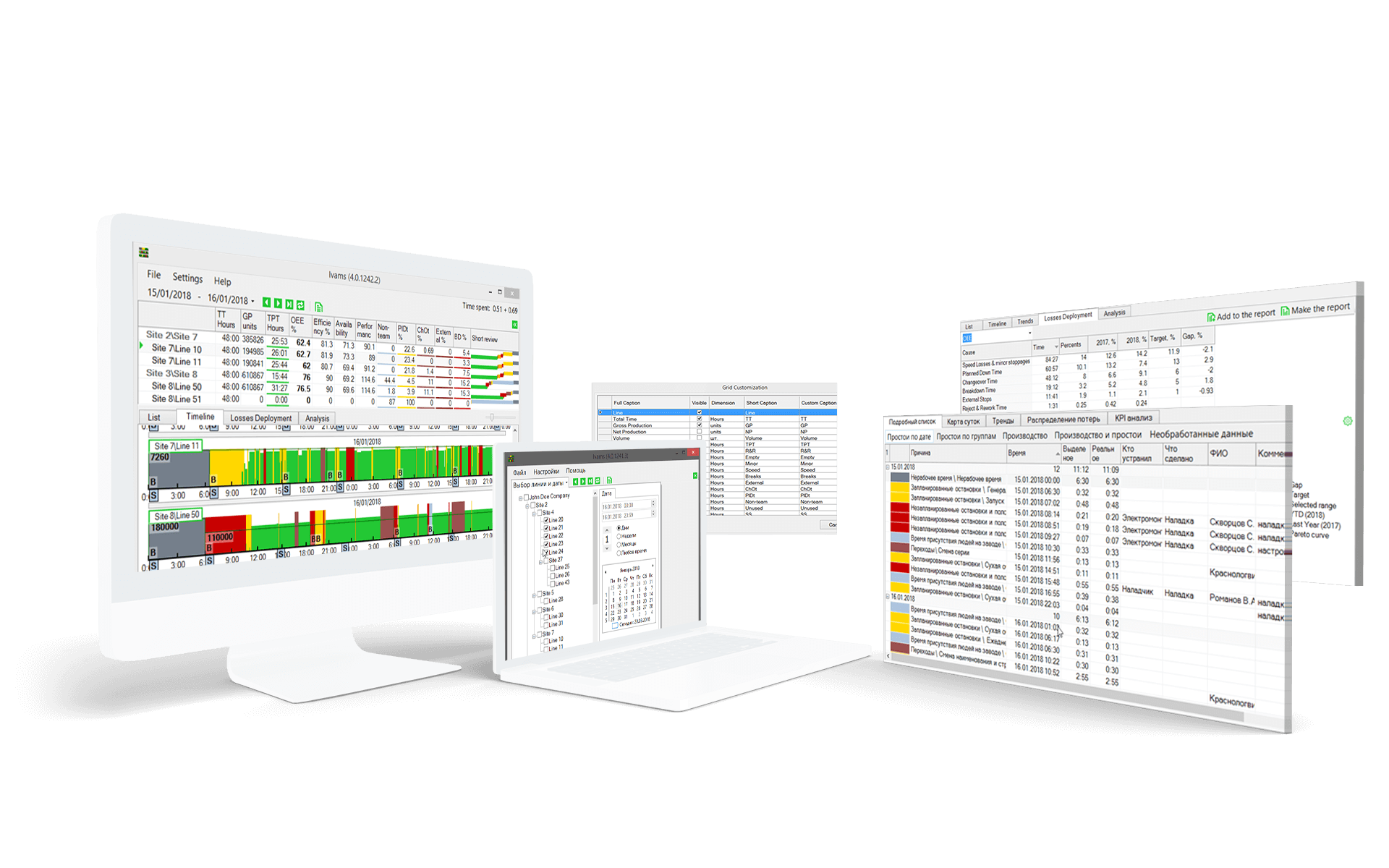

QiVisor Box

QiVisor box - server application, that combines online visualization, the accuracy of the collected data and KPI analysis performed instantly, for any time interval. Meta manufacturing systems is the developer of the Qivisor system. Meta System implements IIoT to small manufacturing enterprises with expertise in engineering and process automation. With verified IIoT solutions, we help manufacturing enterprises increase their efficiency with minimal investment.

Features:

- Visualization of production lines

- Data analysis KPI, OEE

- Manual entry of downtime, product, shift data

- Reports

Opportunities:

- The program calculates the efficiency of the line in the form of KPI. The number and formulas for calculating KPI are configured according to the methodology adopted by the company;

- Data analysis for any period of time;

- Comparative analysis by days, weeks, months, quarters, years;

- Goal tracking;

- Comparative analysis by shifts and product formats;

- Sorting and filtering data by types of downtime equipment, assemblies, parts.

Reporting Features

- The first sheet with a full list of all KPIs for each line without detailing by time intervals and any other parameters

- One sheet with a complete list of downtimes for each line

- One sheet with a detailed KPI analysis for each line.

For whom?

Quality Service Specialist

Quality control of production processes and timely response to emerging problem.

Quality control of production processes and timely response to emerging problem.

Technical Specialist

Control of process parameters with the possibility of optimizing them and reducing energy consumption.

Control of process parameters with the possibility of optimizing them and reducing energy consumption.

Process Engineer

Control of technological process parameters, the ability to analyze the operation of equipment for previous periods, timely response to emerging problems.

Control of technological process parameters, the ability to analyze the operation of equipment for previous periods, timely response to emerging problems.

Owner/Director

Ensure that your staff has access to qualified support in solving production issues and user-friendly software for process monitoring and data archiving. The goal is to reduce the cost of production by optimizing processes and reducing energy consumption. Control of processes that affect product quality will reduce quality risks and minimize returns from the market.

Ensure that your staff has access to qualified support in solving production issues and user-friendly software for process monitoring and data archiving. The goal is to reduce the cost of production by optimizing processes and reducing energy consumption. Control of processes that affect product quality will reduce quality risks and minimize returns from the market.

Technical information QiVisor Box

The system includes:

The system logs downtime based only on the signal of one discrete sensor. Typically, this is the product sensor installed on the slowest machine of all equipment in the production line. The idle time of the slowest machine is the downtime of the whole line. The downtime of the slowest machine may be the result of downtime of other machines or the result of external causes (no materials, no energy, etc.).

- Sensors — production counters

- Local server

- PLC (Controller)

- Application “QiVisor”

- The signal from the product sensor is converted into the number of products produced and the duration of downtime. This data is permanently recorded in the industrial controller, which also acts as an intermediate stand-alone data storage for a period of four days to four weeks.

- From the controller, the contents of the counters are transferred to the database on the SQL server.

- All long line downtimes lasting more than one minute are automatically recorded in the database.

- Short stops less than one minute are not recorded for classification, their total number is counted.

- Shift foremen or people responsible for downtime classification determine the causes of long downtimes and classify downtimes according to the template embedded in the program.