© 2023, Meta Systems LLC

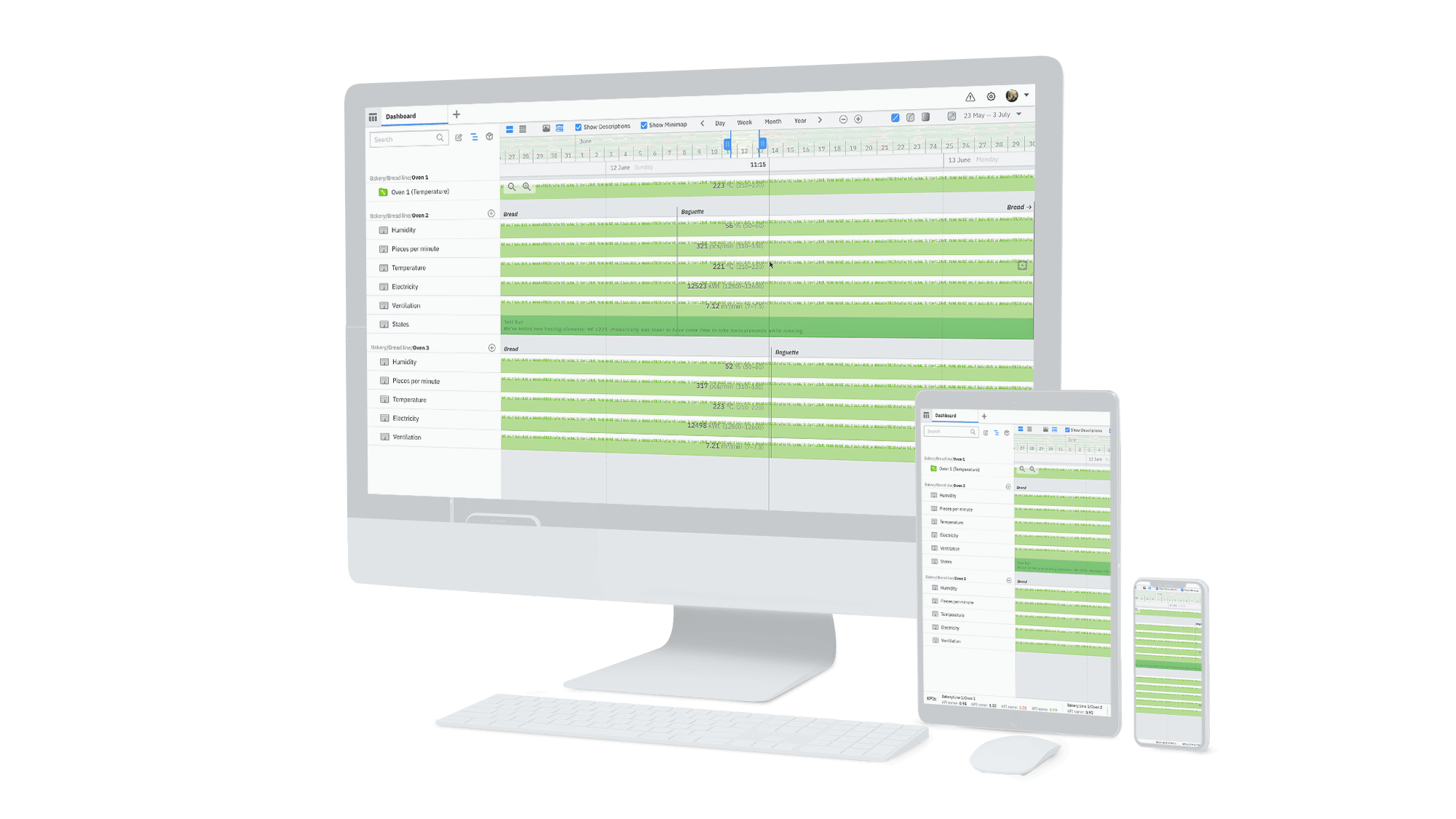

QiVisor Web

QiVisor Web is a web-application for monitoring the operation of any equipment/utilities on-line in different web browsers and on different devices. Online monitoring system for the technical condition and operating parameters of production equipment. Meta manufacturing systems is the developer of the Qivisor system. Meta System implements IIoT to small manufacturing enterprises with expertise in engineering and process automation. With verified IIoT solutions, we help manufacturing enterprises increase their efficiency with minimal investment.

The system includes:

- Monitoring the status of events on the line;

- HMI schemes;

- Alerts notifications;

- Production data monitoring;

- Excel reports;

Features:

- It is possible to track the consumption

- of electricity, steam, carbon dioxide, compressed air, oxygen, etc.)

- It is possible to view the history of indicators for any period (hour, day, week, year)

- Online indicators on charts

- It is possible to add a list of events on the line (downtime, breakdowns, forced stops)

- Opportunity to analyze efficiency (OEE) and line performance

- Possibility to export excel report

Advantages:

- An easy-to-use and affordable tool to control production costs;

- Saving time for information search;

- Availability of video tutorials;

- Ease of setting up notifications about deviations in equipment operation;

- Providing enough data to make the right decisions;

- Identify chronic (frequently recurring) causes of downtime and measure their impact on performance loss.

What can be monitored?

- Monitoring of utilities (water, steam, electricity)

- Capacitive Equipment Load Monitoring

- Line Status/Downtime

- Equipment washing monitoring

- Monitoring the pasteurization process

QiVisor Web HMI

QiVisor Web Demo HMI

QiVisor Web Online indicators on charts

QiVisor Web Status monitoring on charts

For whom?

Quality Service Specialist

Quality control of production processes and timely response to emerging problem.

Quality control of production processes and timely response to emerging problem.

Technical Specialist

Control of process parameters with the possibility of optimizing them and reducing energy consumption.

Control of process parameters with the possibility of optimizing them and reducing energy consumption.

Process Engineer

Control of technological process parameters, the ability to analyze the operation of equipment for previous periods, timely response to emerging problems.

Control of technological process parameters, the ability to analyze the operation of equipment for previous periods, timely response to emerging problems.

Owner/Director

Ensure that your staff has access to qualified support in solving production issues and user-friendly software for process monitoring and data archiving. The goal is to reduce the cost of production by optimizing processes

and reducing energy consumption. Control of processes that affect product quality will reduce quality risks and minimize returns from the market.

Ensure that your staff has access to qualified support in solving production issues and user-friendly software for process monitoring and data archiving. The goal is to reduce the cost of production by optimizing processes

and reducing energy consumption. Control of processes that affect product quality will reduce quality risks and minimize returns from the market.

Technical information QiVisor Web

Stages of implementing QiVisor web:

1

Demo registration

Explore the capabilities of the system in a demo account for implementation in your production.

2

Coordination of technical specifications

We select sensors and controllers according to your application.

3

System connection

You get a file for a controller or controller + installation instructions.

4

Online monitoring 24/7

Control your production in a web application.

Security

- Your data is stored on the cloud server only in encrypted form (Encryption-at-Rest)

- A separate infrastructure is deployed for each client

- Data is sent encrypted (over a closed HTTPS connection)

- Backups are made every day (all data), stored for 1 month