© 2023, Meta Systems LLC

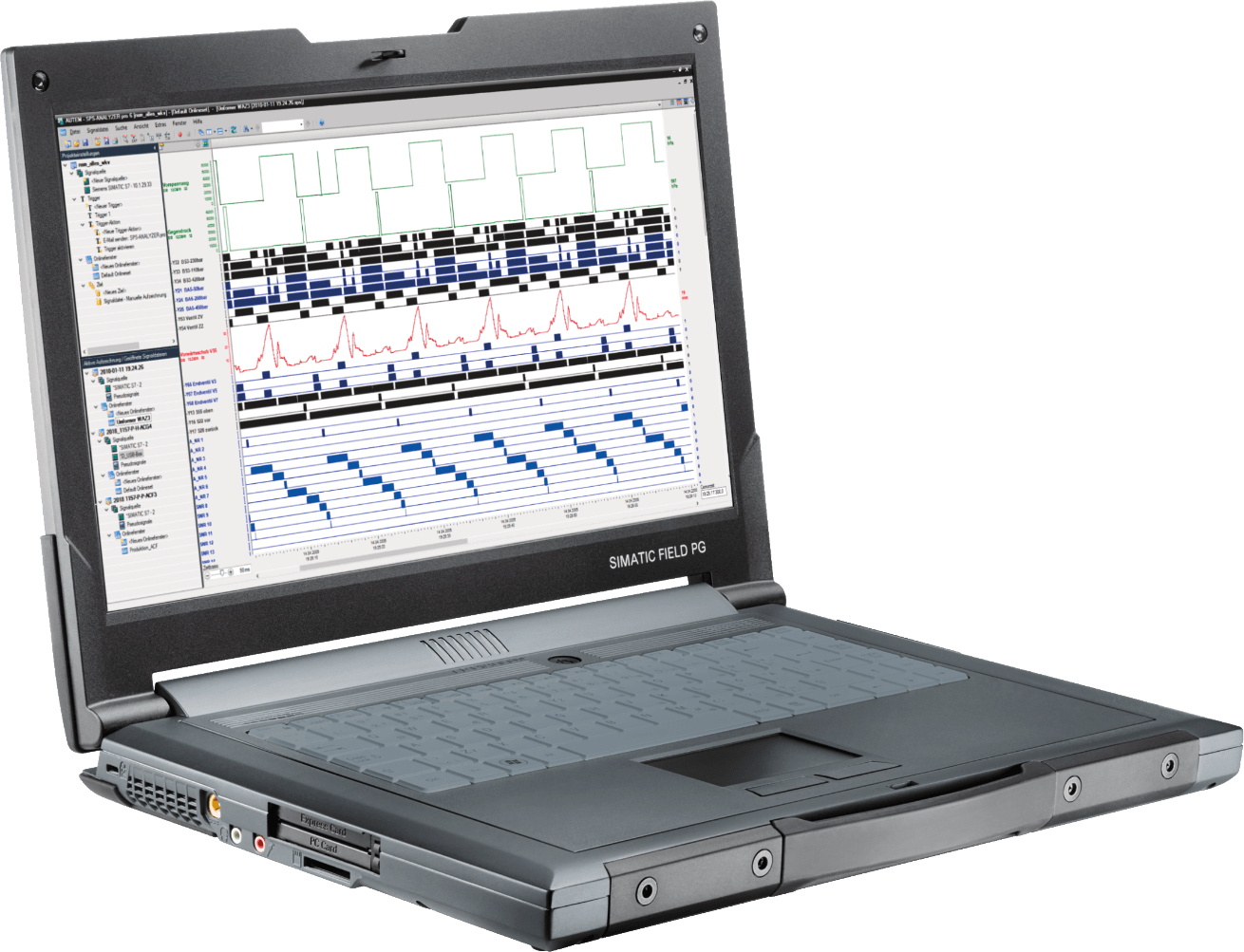

PLC-Analyzer pro 6

PLC-ANALYZER pro 6 from AUTEM is a software package for the logical analysis and recording of measured values in PLC controlled equipments.

PLC-ANALYZER pro 6 simplifies collecting, presenting and evaluating PLC signals such as input, output, flags, timer, counter, data block data. Meta manufacturing systems is official distributor of AUTEM GmbH. Meta System implements IIoT to small manufacturing enterprises with expertise in engineering and process automation. With verified IIoT solutions, we help manufacturing enterprises increase their efficiency with minimal investment.

PLC-ANALYZER pro 6 simplifies collecting, presenting and evaluating PLC signals such as input, output, flags, timer, counter, data block data. Meta manufacturing systems is official distributor of AUTEM GmbH. Meta System implements IIoT to small manufacturing enterprises with expertise in engineering and process automation. With verified IIoT solutions, we help manufacturing enterprises increase their efficiency with minimal investment.

Fields of use

- Breakdowns diagnostics;

- Troubleshooting sporadic errors;

- Optimization of cycle time;

- Permanent recording of measured values;

- Predictive maintenance;

- Quality guarantee

- TPM/OEE, EU Machinery Directive

- Condition Monitoring.

The real-time display allows you to observe the waveform of the signal in live. Signal analysis and evaluation takes place already during recording.

In addition to permanent recording you can specify trigger conditions for logging specific events. This makes it possible to specifically record infrequently occurring sporadic errors for subsequent analysis.

In addition to permanent recording you can specify trigger conditions for logging specific events. This makes it possible to specifically record infrequently occurring sporadic errors for subsequent analysis.

For whom?

The technical manager —

using this system will be able to find and diagnose sporadic faults. Monitoring the condition of the equipment will allow determining the time of preventive maintenance to eliminate costly breakdowns.

using this system will be able to find and diagnose sporadic faults. Monitoring the condition of the equipment will allow determining the time of preventive maintenance to eliminate costly breakdowns.

The director of the manufacturing plant — will be able to unambiguous determine the warranty case in case of equipment malfunction, due to the objective measurement and recording of the process signal.

The technologist — will be able to optimize the cycle in his production due to the investigation of delay times of a production system.

Technical information PLC-Analyzer pro 6

Technical features

- All-in-One: Project setup, recording, analysis in one tool

- Pure software solution: No special additional hardware required

- No need to make any changes in the PLC program

- Data recording via existing connection to the PLC (Ethernet TCP/IP, serial, Fieldbus, …)

- High-performance sampling by specific PLC drivers

- Recording of input, output, flag, timer, counter, peripheral, data of data blocks and other PLC variables

- Use symbols directly from the PLC programming software, e.g. load TIA projects and use symbols / settings

- Import symbols also directly from TIA PLCs

- Optimized data blocks (S7 1200/1500): Variables direct readable

- bit-, byte-, word-, double- or quad-word format

- Pseudo signals: generating of virtual signals by [complex] calculation from recorded signals

- Simultaneous acquisition from several PLC systems / also different manufactures (e.g. SIMATIC S7 + CoDeSys)

- Up to 250 signal sources / 16 million variables

- Videotrack (optional): Camera recording synchronous with PLC signal capturing

- Cycle precise recording for different PLC systems

- Supports PC based PLC (e.g. Beckhoff TwinCAT) and PLC simulators (e.g. S7-PLCSIM)

- Recording modes: continuous recording, trigger-, time-controlled

- Enable/Disable of addresses and triggers during recording

- Real-time online display of signals

- Comfortable PLC signal selection for online window by drag & drop

- Analysis of signal data possible while recording

- Highly accurate display of signals with short-term fluctuations of measured values („spikes“)

- Comfortable trigger definition by drag & drop

- Trigger on binary and register values with AND/OR/XOR/RS and cascading

- Pre- and post-trigger time freely selectable

- Extensive trigger actions: Notification (E-Mail, SMS, acoustic announcement, pop-up-window), any PC-commands

- Comparing of signal files

- Search function: search for trigger, edge, bit pattern, register values, time and notes – even across several signal files

- Time difference measurement and automatic bit measurement

- Relative and absolute data-time

- Flexible signal scaling and normalization – e.g. conversion in physical units or min-max-ajustment of measured value

- Number format: decimal, hexadecimal, binary, ASCII, REAL (floating point), S5-TIME, TIME, DATE, DATETIME

- Projects for pre-configuring and automating data acquisition runs

- Extreme robust and compact file format

- Multiple data targets at the same time: e.g. simultaneous writing of signal file and CSV file

- Export of signal files: PDF, CSV, Excel, HTML, graphic formats

- Import of CSV files: visualisation of other measure values

- Printing of signal files and measurement configuration

- Multilingual user interface: German / English

- System requirements: Microsoft® Windows 7/8/10/11 (32/64-Bit)

- AD_USB-Box® (optional): Recording of external voltage and current with external box connected via USB

- Videotrack module (optional): The Videotrack module enables video recording time-synchronous to PLC signal capturing.

- BLACKBOX 4 Edge (optional): Ultra-compact industrial PC for control cabinet; long-term process data recording, monitoring, remote maintenance

PLC driver